The Staffordshire Cheese Company

The Staffordshire Cheese Company has been making artisan cheese for over twenty-five years. I recently spent a day in their creamery in Cheddleton, learning about and watching them produce their award-winning, handmade cheeses. I even played a teeny part in the production of one of my favourites.

As I write this, supermarket shelves are being stripped bare by panic buyers during the COVID-19 coronavirus outbreak.

The sight of empty shelves, normally full of food, is driving many to local producers and suppliers for the first time. Dairies for home delivered milk, butchers, farm shops, greengrocers and artisan bakers.

So it’s perhaps more important than ever that we give a shout out to those local food producers who’ve been quietly going about their business for many years.

And maybe even get some of those new customers to stick around when this crisis is over.

One of my local favourite producers is The Staffordshire Cheese Company.

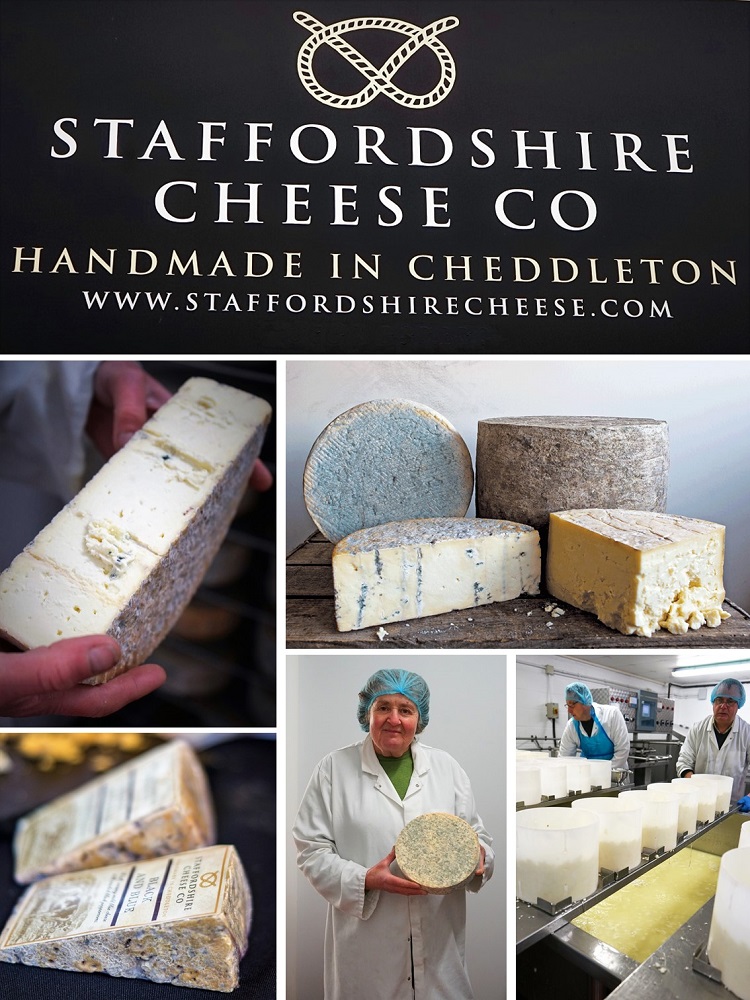

THE STAFFORDSHIRE CHEESE COMPANY

I think The Staffordshire Cheese Company must have been one of the first local suppliers I came across when we moved to the Moorlands.

Previously living in a city, we’d used supermarkets for virtually all our food shopping. But we resolved to kick the habit when we moved.

Looking out for local food and independent businesses, we’d often see Staffordshire Cheese at markets such as the Leek fine food market.

With an array of attractive-looking wedges of cheese piled in wicker baskets, plus plenty to try before you buy, myself and partner ID became real fans of this handmade product.

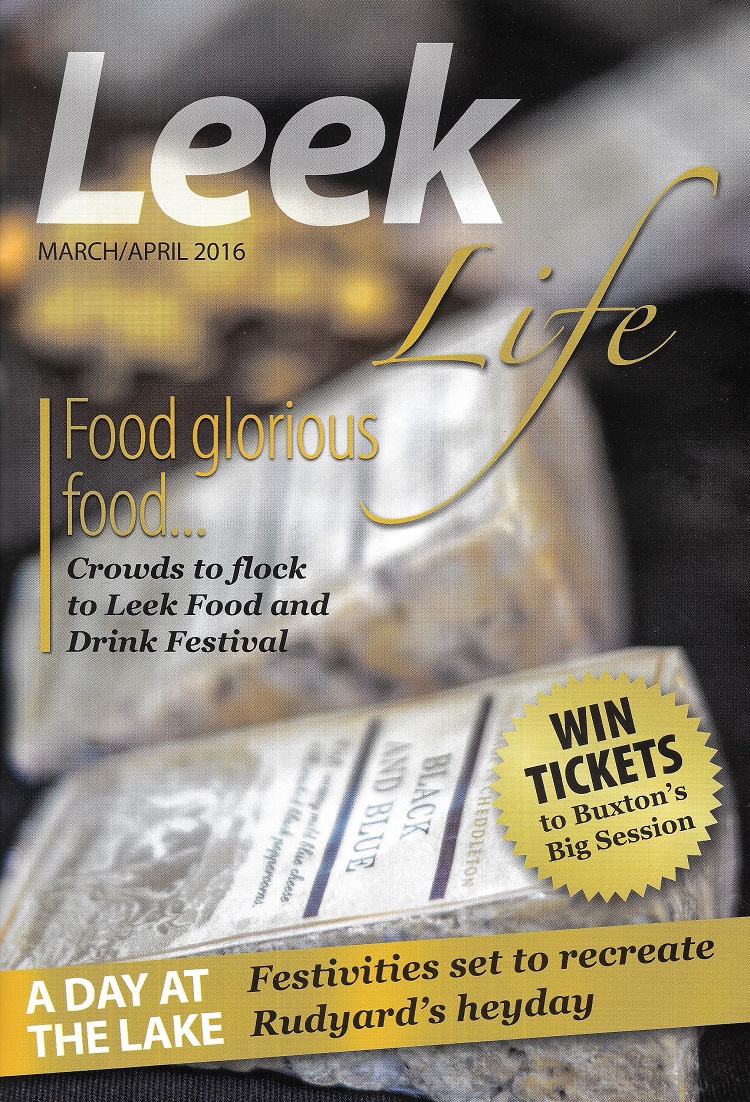

Some Staffordshire cheese even ended up onthe cover of Leek Life magazine courtesy of ID who, as well as his day job, has a small photography business.

Besides their classic Staffordshire Cheese, Cheddleton Original and Oak Smoked Cheddleton, I developed a particular liking for Dovedale Blue.

So I was particularly happy when I discovered that, on the day I was going to spend with The Staffordshire Cheese Company recently, I’d be lending a hand making this wonderful cheese.

A BIT OF HISTORY

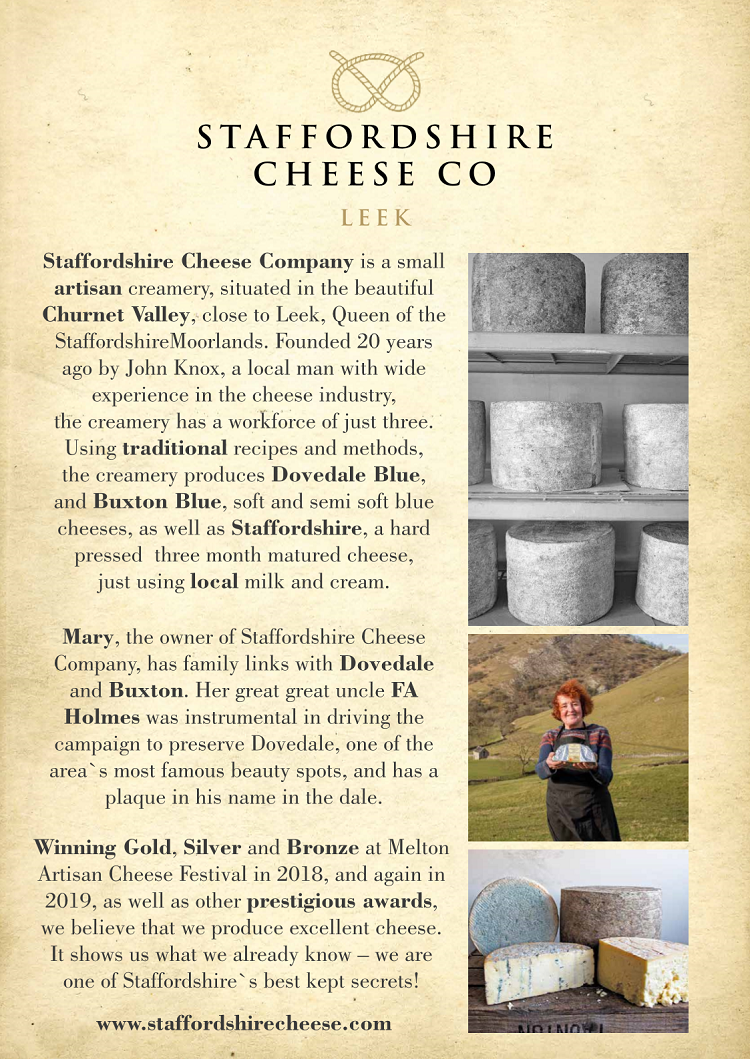

Mary Button (affectionately known as ‘Mary from the dairy’) is the current owner of Staffordshire Cheese and was my guide for the day.

She took over in 2017, but the company has a longer history than that.

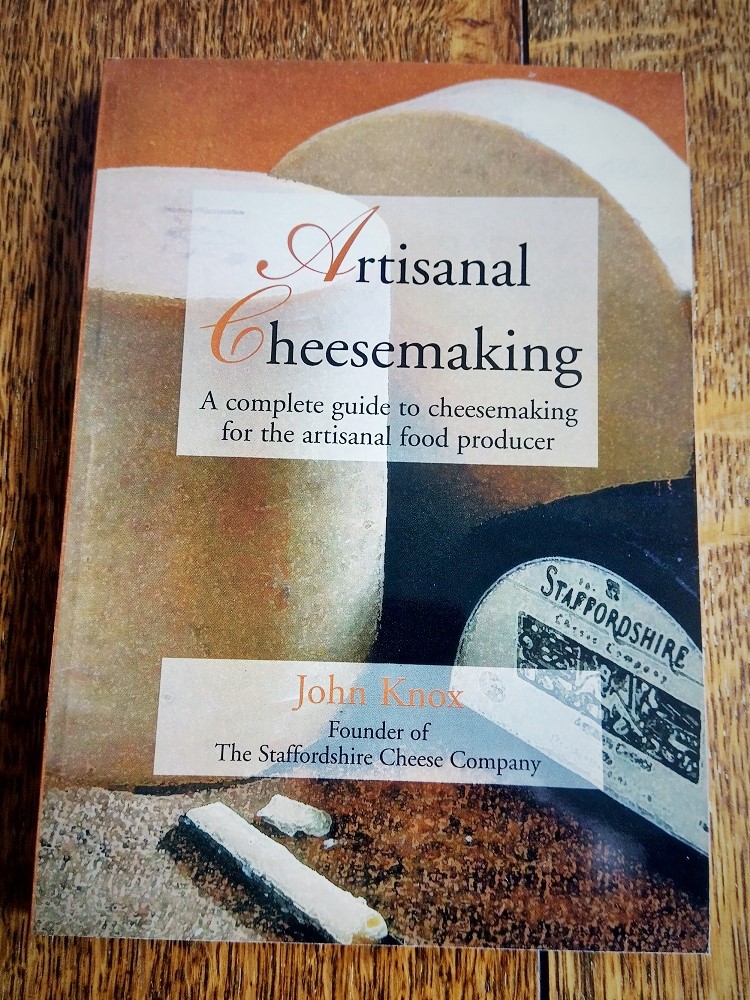

It was founded in 1994 by John Knox who developed a passion for cheese from an early age.

In his book Artisanal Cheesemaking, a copy of which I was kindly given after my visit, John says that at the age of seventeen he took a holiday job in a Scottish cheese factory. There he washed cheese vats, scrubbed floors and tasted “some of the most amazing… cheese made in the world.”

They obviously had a high opinion of their product too. John recalls that on seeing him carrying a huge, round cheese, the cheesemaker said, “If you’re going to fall son, make sure it’s on your back, so that you don’t damage my cheese.”

Nonetheless, John enjoyed the experience as he ended up having a long career in the dairy industry. However, it was only after redundancy and a change of direction that John started his own experiments in cheesemaking.

The result was the setting up of The Staffordshire Cheese Company. Just four years later, John’s first cheese, Archie’s Choice won first prize at the Bakewell Show.

Further success followed. This included being one of Rick Stein’s ‘Food Heroes’ and receiving Protected Designation of Origin (PDO) status for a number of cheeses.

Sadly, John eventually had to give up cheesemaking due to ill health. The company was sold to local artisan beer brewers, and it was in that guise, as sister company to the Staffordshire Brewery that I first came across The Staffordshire Cheese Company.

MARY FROM THE DAIRY, STEVE & NEIL

With Mary Button taking over Staffordshire Cheese, that brings us up bang up to date.

After meeting and chatting to Mary for just a short while (and learning a lot about cheese in the process), I was surprised to learn that prior to 2017 she had no experience of cheesemaking.

Although she now lives on a farm, Mary’s not from a farming background. Herself and a friend used to sell other peoples’ cheeses at markets and that’s how she met her partner, who is a farmer.

Also with Mary at Staffordshire Cheese are Steve and Neil. Both worked there under the previous owner and it’s clear their knowledge and experience are vital to the operation.

Of course, these days, you can’t just be a cheesemaker. As any small business owner knows, a huge amount of work is involved in marketing your product, making sales, having an online and social media presence, dealing with finances etc. And that’s without the added job of meeting environmental health and food hygiene requirements.

So, with all that to do, I was extremely grateful that the team at The Staffordshire Cheese Company allowed me to come in and see what it was all about.

CHEESEMAKING

Before my visit, all I really knew about cheesemaking was that it starts with milk being separated into curds and whey and that the curds are used to make the cheese.

I’ve made simple fresh cheeses like cottage cheese and Indian paneer. But these only involve separating the curds (the solid part) and whey (the liquid part) by adding lemon juice or vinegar. You don’t then do a lot with the curds, other than pressing them into a block if you want to make paneer.

But proper cheese is a whole different ballgame.

When I arrived at The Staffordshire Cheese Company, after a chat with Mary it was time to get on my hairnet, overall and wellies then wash and sanitize my hands.

The place has to be scrupulously clean and I was constantly aware of what I could and couldn’t touch. Throughout the day we were all regularly washing and sanitizing our hands, putting on and taking off gloves as we moved around the different areas.

PASTEURIZATION & FIRST STAGES

The milk used at Staffordshire Cheese is sourced from various local farms. When it arrives, it goes straight into the tank you see on the right of the image below.

The first job is pasteurizing the milk, which Steve did using the pasteurizer you see in the middle.

The milk is heated so that any harmful bacteria are killed. Pasteurization also improves the keeping qualities of the milk and any products made with it.

After pasteurization, the milk is taken down to a lower temperature and starter cultures added. This happens in the vat which is top left in the picture.

I thought the steps up to this point were very similar to those I use for my Homemade Yogurt. When I make yogurt, I heat up milk and then bring the temperature down before adding some of my last batch of yogurt. This acts as the starter culture, containing the live but harmless bacteria which turns lactose in the milk into lactic acid. This thickens the milk and makes it more sour i.e. gives you yogurt.

To make my yogurt into Greek-style, thick yogurt, I line a sieve with muslin cloth and strain some of whey out for a couple of hours.

Strain it for even longer and you get labneh, often referred to as yogurt cheese. But it doesn’t have that distinctive, appetizing ‘cheesy’ taste and smell.

So, one of the things I wanted to learn on my visit was, what is the difference between yogurt and cheese?

WHAT IS CHEESE?

The bacteria in my homemade yogurt are lactobacillus acidophilus and bifidobacterium. I know this because that’s what it said on the little pot of commercial yogurt I used as the starter in my very first homemade batch. But I discovered that cheesemaking uses different bacterial cultures.

I knew that rennet is also used in cheesemaking but didn’t understand how or why.

It turns out that the enzyme rennet (traditionally of animal origin, these days almost always from plants) curdles the milk so it can be separated into curds and whey. Which is just like when I add lemon juice to make Indian paneer.

But the important thing is that rennet results in much firmer curds. That’s why you can turn them into all sorts of hard and semi hard cheeses.

Trying to get my head around what determines the characteristics of the huge number of cheeses in the world, Mary said to think of them as having been made by following particular recipes.

These recipes will use different starter cultures, different quantities of starter and rennet etc. There’ll also be differences in temperature, levels of acidity and a whole host of other factors.

SCIENCE & ART

In Artisanal Cheesemaking, Knox says that making artisan cheese combines both art and science. Even as a newbie, I could see this was the case.

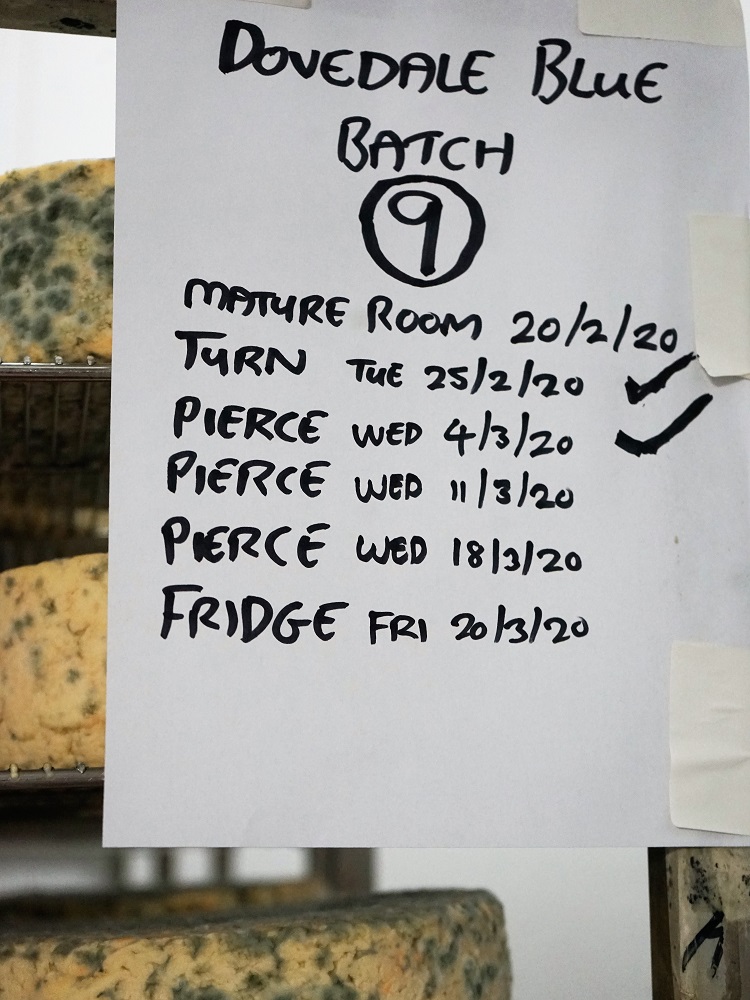

For instance, in the image below, you can see on the table that Steve has the Dovedale Blue ‘recipe’ sheet (which is also a record of that batch). At this point he’s checking that the correct acidity has been reached. That’s the science bit.

But he will still run the curds through his fingers, using his experience to check that the texture is right before going on to the next stage in the process.

Most of the time, although there is also a lot of physically demanding work, activity went on steadily without rush. I found the atmosphere in the place rather calming. I even got transfixed for a while, watching the cutting and stirring of curds and whey up on the platform.

Meanwhile, Mary dealt with orders from stockists like Denstone Hall. Neil cut, weighed and packed big chunks of classic Staffordshire Cheese.

However, once the cheese moulds were lined up on top of the tank which would receive the curds and whey from the vat above, there was a definite air of expectation.

I admit I was quite excited now, the anticipation increasing each time someone called out, ‘how long, Steve?’

A CHANGE OF PACE

As soon as the curds and whey came hurrying down, the pace changed and it was all hands on deck.

Working fast, we scooped up the curds and whey in colanders. A bit of a shake and the curds were tipped into the moulds, Neil and Steve sliding over a new tray of moulds as each was filled.

I loved getting my hands into the warm mixture and it was satisfying to be a part of it. Whether I was more of a hindrance than a help though, I wouldn’t like to say.

Breaking off to take photographs from up on the platform, it was noticeable how the temperature of the dairy had changed. From being quite chilly first thing, the pleasantly milky, warm air rose and started to condense on my camera lens.

As we removed the curds, the whey ran out of the bottom of the tank and drained away. When I mentioned that I used the whey strained from my yogurt in breadmaking (it’s full of protein and adds flavour), Mary went and fetched a bottle and filled it for me to take home.

Mary decided to turn a couple of the cheeses into their Black and Blue by adding cracked black pepper. This cheese is recommended for putting on a steak or burger. Sounds good to me.

Moorlands Eater cheese!

As there was a small amount of curds left which wasn’t enough to make a large cheese, Mary suggested I fill one of the smaller moulds to make my very own Dovedale Blue. I’m looking forward to collecting that when it’s ready!

When all the whey had been transferred to the moulds, the cheeses were left to drain for thirty minutes before turning.

Even after this short time, I could see the curds were sticking together to form a mass. Now I understood why we had to work quickly getting them into the moulds.

The cheeses are turned for a second time before being put on the shelf and the work of cleaning can begin.

A CHEESE LOVER’S HEAVEN

Besides watching the cheesemaking, and playing my little part, during my day at the Staffordshire Cheese Company I also had a tour of all the different areas. And got to taste some cheese of course.

If you’re a cheese lover, then you’ll be in heaven visiting the maturing rooms full of huge wheels of cheese.

I think they’re beautiful things. Their crusty rinds are intricately coloured and craggy looking, almost like an old plaster wall.

And of course, the smell is wonderful.

BLUE CHEESE

Particularly pungent is the blue cheese room. This contained shelves stacked not just with Dovedale Blue but also Buxton Blue.

Buxton Blue has a much stronger taste than the creamy Dovedale. It’s got quite a kick and I thought I didn’t like it.

But it grew on me and I even ended up liking a very mature piece that Mary gave me to try, despite ‘farmyardy’ being my initial thought.

I’d often wondered why, when you get a blue cheese, there are horizontal lines of blue inside. Well that mystery was solved on my visit.

To encourage the mould to travel into the interior of the cheese, they’re regularly pierced with metal wires or skewers.

Obvious once you know, isn’t it?

To see how a cheese is maturing, a cylinder of cheese is taken out using a cheese iron.

I loved having a go at this. I had to slowly turn the iron as I pushed it into some Dovedale Blue then gradually draw it out.

First, we just looked. Then we considered the texture by rolling it between finger and thumb. Then a sniff. Finally, a taste.

At this early stage, the cheese was creamy and fresh tasting with just a hint of blue.

If The Staffordshire Cheese Company ever needs a dedicated cheese grader, you have my number 😋.

VARIETY

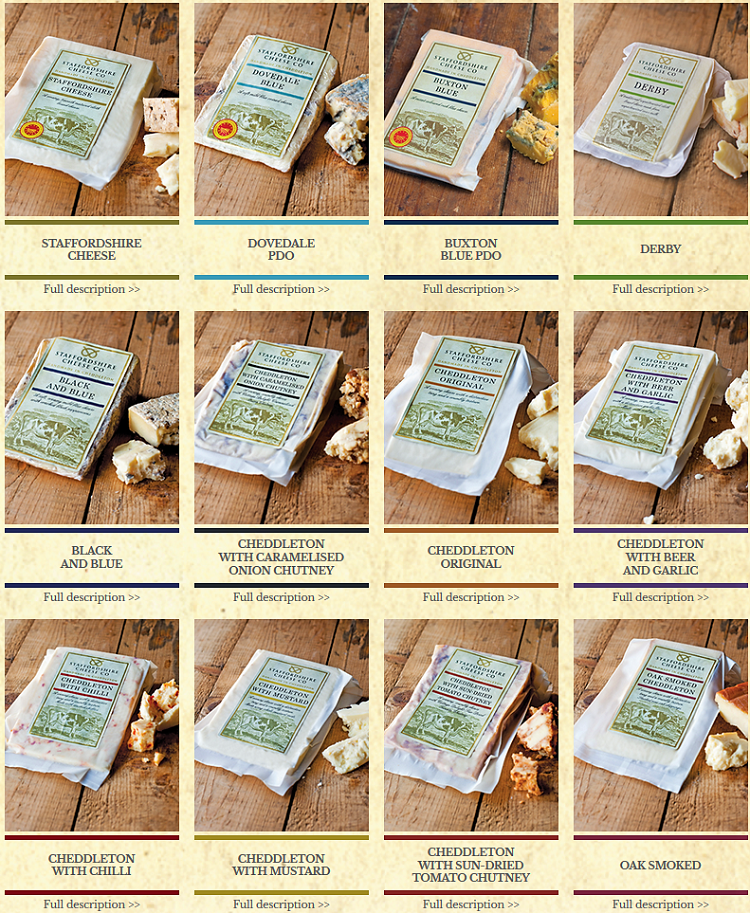

I know that blue cheeses aren’t for everyone, but they’re just one element of Staffordshire Cheese’s output. So I’m sure anyone who loves good quality cheese will find plenty to enjoy.

Why not start off with some of their simply named Staffordshire Cheese? This has a creamy but complex flavour.

If you like smoked cheese, try Oak Smoked Cheddleton which is another favourite of mine. I was interested to learn that it’s smoked by The Port of Lancaster Smokehouse because I’m a big fan of their Tuscany Style Smoked Pancetta (great for pasta, soups and stews).

Cheeses flavoured with things like chilli, chutney or mustard are very popular these days. But many of those you’ll find for sale aren’t always the best quality.

However, select some from The Staffordshire Cheese Company’s range and you’ll still be getting handmade, artisan cheese. Just with a little extra something.

I don’t buy flavoured cheese very often. But I did recently get some Cheddleton with Beer and Garlic. It had a good, strong garlic flavour which went well with some homemade crackers for lunch.

Or how about subtly sweet Cheddleton with Caramelised Onion Chutney, or Cheddleton with Mustard?

And did you know The Staffordshire Cheese Company also makes quality butter?

Besides my bottle of whey, I left with some of that butter and also a wonderful goat’s milk cheese Mary has been experimenting with.

WHERE TO BUY STAFFORDSHIRE CHEESE

There’s no shop at the Cheddleton site, although they may let you pick up some cheese if you ring ahead first on 01538 361725.

But you can buy Staffordshire Cheese at farmers’ markets, loads of farm shops, delicatessens and also some Morrisons supermarkets.

The following are just a few stockists I know:

Jackson’s Nursery Farm Shop, Bagnell

VISIT THE STAFFORDSHIRE CHEESE COMPANY

Would you like to spend a day at The Staffordshire Cheese Company?

While it might not be possible to visit during the current coronavirus outbreak, it’s well worth thinking about for the future. I think a tour would also make a lovely birthday gift for a cheese-loving family member or friend.

I was made to feel very welcome and loved my visit. It gave me a whole new appreciation of cheese and, as with attending my first whisky tasting event earlier this year, learning a little has spurred me to want to learn a whole lot more.

Tours are normally available for individuals or groups of up to three people. Contact the company to find out future availability and prices.

HIGHLY RECOMMENDED

Having enjoyed The Staffordshire Cheese Company’s quality products ever since I first moved to the county, it was fascinating to see how they are made.

Dipping into founder John Knox’s book, I can see that since his day things have developed. For example, there’s a photo in there of cutting by handheld vertical knives rather than that machine that had me so hypnotised.

But the cheese is still handmade, a local, artisan product requiring skill, experience and judgement.

And you can tell that from the great taste.

SUPPORT LOCAL PRODUCERS & SUPPLIERS

I think that if the current crisis teaches us anything, it should be that we can no longer take our food for granted. Nor the people who produce it for us and get it on the shelves.

If you already love Staffordshire Cheese, tell more people about it and get them to buy it too.

And if you’re one of those people who (no longer guaranteed to get what you want, when you want, from the supermarkets) are only just discovering local produce and independent suppliers, when this is all over please continue to support those farmers, butchers, dairies, greengrocers, bakers and cheesemakers who have fed you.

UNLESS OTHERWISE INDICATED, ALL PHOTOS © MOORLANDS EATER & NOT TO BE REPRODUCED WITHOUT PERMISSION

Disclosure

I was not charged for my visit to The Staffordshire Cheese Company or the products I took home. However, as always, the opinions given are honest and based on my own experience.

Where a product or service has been provided without charge then a disclosure such as this will always be included in the post.

Read more about working with Moorlands Eater on my About page here

I read this with interest and enjoyed reading all about as my Grand daughter gave me a cheese making kit for Christmas. I thought that it was not for me but now I can’t wait to have a go. If I see Staffordshire Cheese in my area I will buy some. Again, Thank you.

Thanks for your feedback Avril! Pleased to hear I have played a small part in sparking your interest in cheese making and Staffordshire Cheese.

Thank you for your interesting and detailed article on making artisanal cheese.

Thank you for your kind comments, Dale!